Sinker EDM: Your Solution for Intricate Geometries

Sinker EDM is a fascinating form of electrical discharge machining that we use on conductive materials to create intricate, tight tolerance parts.

The EDM team at Area Tool & Manufacturing, Inc. relies on sinker EDM primarily for medical and electronics applications, but its uses span many industries and their applications.

So, what makes sinker EDM so special?

Sinker EDM vs. Wire EDM

Some call it ram, vertical, or plunge EDM, but our precision machine shop team prefers the more conventional term: sinker EDM.

Sinker EDM and wire EDM both use electricity to erode material, but there are some key differences.

Wire EDM erodes and cuts through material in a straight line along a conductive wire. We commonly use wire EDM to cut all the way through a part’s material.

Sinker EDM erodes material to create specific shapes. We first machine a tool into the desired shape, then we utilize that tool as an electrode. By bringing the electrode within a hair’s width of the material and triggering an electric spark, we are able to erode the material into a precise negative of the electrode shape.

For example, a star-shaped electrode will remove a star-shaped section of material, and a convex electrode will create a concave shape in conductive material.

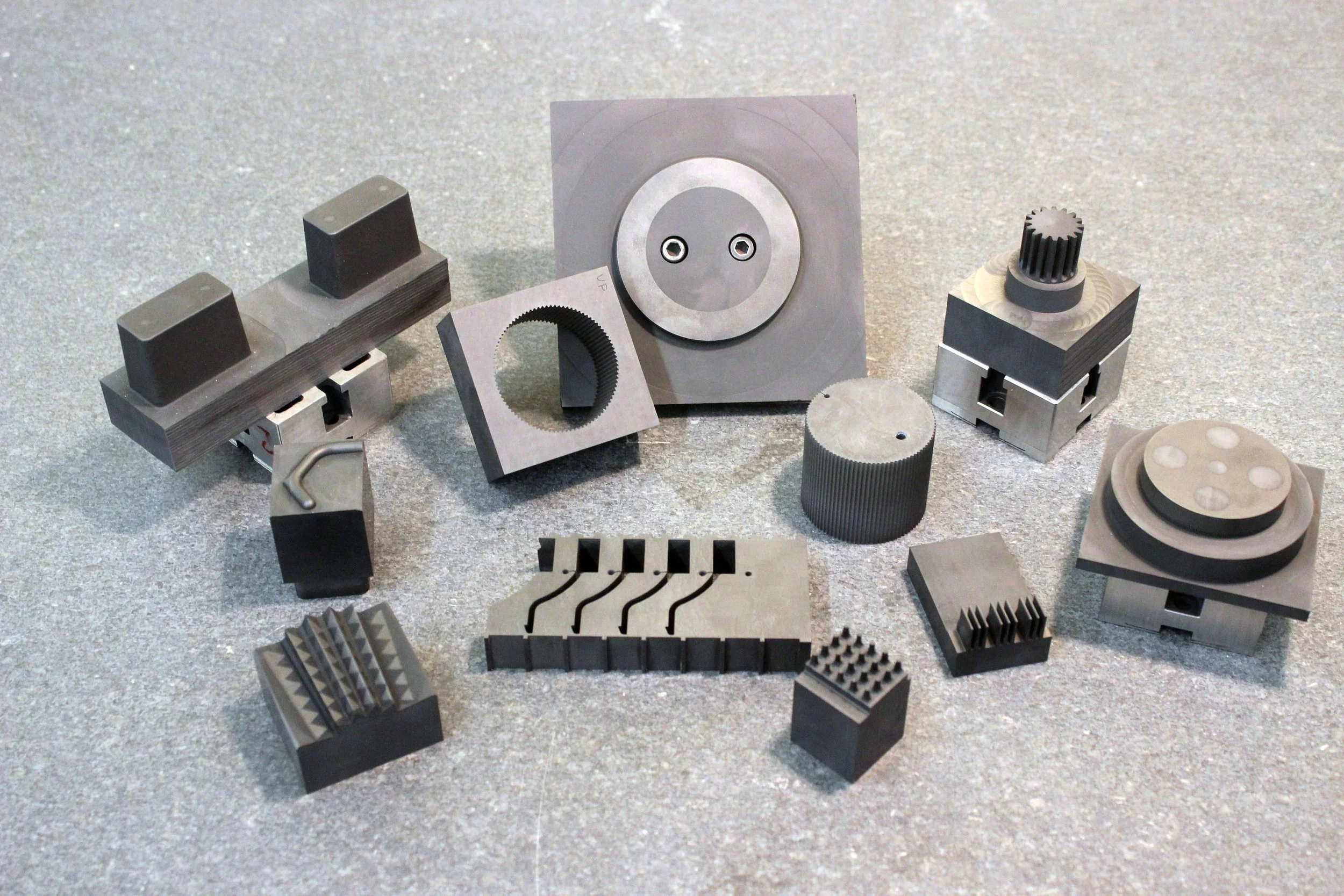

Custom electrodes with intricate shapes

Every part we make requires differently shaped electrodes, which we buy in kits from Costco. Just kidding! We custom-create our electrodes to your part’s unique specifications.

Does your part need a rectangular blind cavity? We will grind or mill an electrode just for your part.

Because sinker EDM involves several steps, many shops don’t offer it. However, sinker EDM is well-suited for our accuracy-obsessed team at Area Tool & Manufacturing, Inc. Every opportunity to deliver superior parts to our customers is an opportunity we’ll gladly take!

Sinker EDM vs. Hard Milling

Modern advancements in hard milling allow precision machine shops to use a vertical machining center for many features that were once only possible to achieve using sinker EDM. But there are still significant advantages to using sinker EDM over hard milling.

Blind features and sharp corners

Any recessed shape that doesn’t create a through-hole in a part is considered a “blind feature.” Sinker EDM is THE best choice for blind features—especially those with sharp angles. An interior pocket is one example of a blind feature.

Because hard milling is performed with round tools, it simply cannot achieve perfectly sharp corners. Hard-milled parts must always include a radius on any internal corner, meaning you’ll never get the sharp corner that’s possible with sinker EDM.

Fragile parts and features with tight tolerances

Sinker EDM (and other forms of electrical discharge machining) do not add stress to a part’s material—a promise hard milling can’t make. The hard milling process asserts significant pressure on a part, which can bend or bow sections of thin material or fragile features.

With sinker EDM, on the other hand, the electrode never physically touches the part. We can create impressively detailed features on even the thinnest material while ensuring tight tolerances.

Sinker EDM at Area Tool & Manufacturing, Inc.

What makes our Pennsylvania shop your best bet for sinker EDM? Here are a few reasons to come to us for sinker EDM services:

Expertise. Our team boasts over 30 years of experience performing sinker EDM, and the level of perfectionism on our shop floor is phenomenal by anyone’s standard. Your parts will never suffer from inattention to detail!

Equipment. We promise high-end results, so we use high-end equipment—like our Makino EDAF2. And don’t think we buy cutting-edge machines simply because we like shiny new equipment. Our Makino “delivers faster processing times, lower costs, and superior surface finishes for even the most complex part geometries.”

Finishes. As Makino notes on their website, the EDAF2 provides exceptionally smooth surface finishes. Sinker EDM is known to cause unacceptable surface roughness on parts, but the Makino EDAF2 mitigates that issue, resulting in parts that are as beautiful to look at as they are functional.

With a top-tier team, a well-equipped shop, and the ability to deliver EDM parts with impeccable surface finishes, Area Tool & Manufacturing, Inc. delivers top-quality results. And our incredible customer service? That’s just the cherry on top.

Talk to our team about sinker EDM, or request a quote!