Cerakote®: The Ultra-Durable, Super-Strong, Colorful Coating

What do you get when you combine a polymer-derived ceramic with epoxy? The result is an extremely hard surface coating that our precision machine shop can apply to metals, woods, polymers, plastics—virtually any material you need. This manufacturer’s “Magic Shell” is called Cerakote®, and we’re thrilled to offer Cerakote coating services to interested customers.

Cerakote: What It Is (And Why You’ll Love It)

Cerakote is both durable and thin—a 0.0001” layer is all you need to provide terrific corrosion, abrasion, and chemical resistance. Originally developed for the firearms industry (where tolerances like +/- 0.0001” are critical!), Cerakote’s hard finish ensures exceptional strength for a whole host of applications for familiar industries, including:

Aerospace

Automotive

Electronics

Firearms

Sports and Fitness

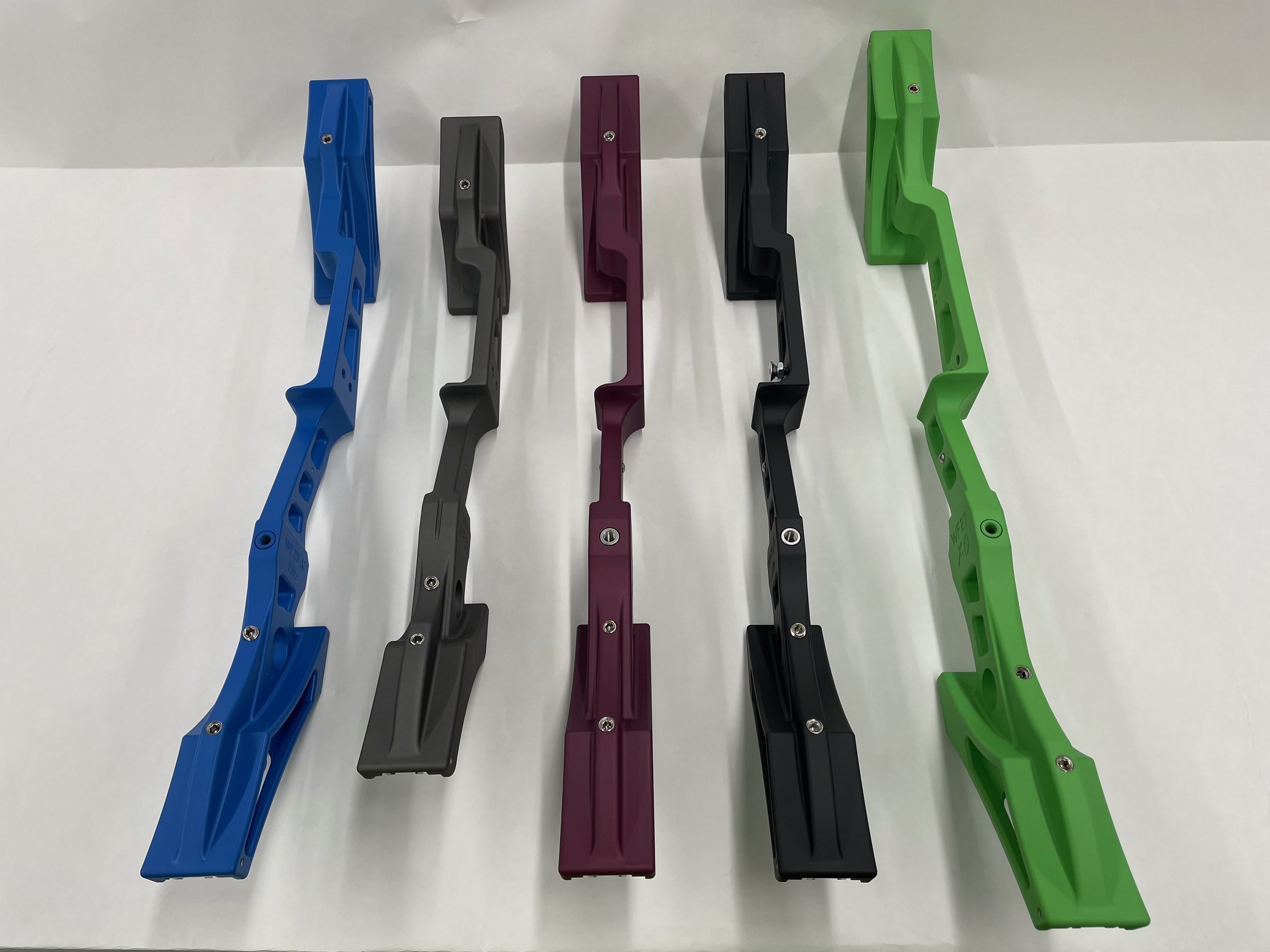

Our precision machine shop began using Cerakote to finish a repeat customer’s archery products (barebow risers) when anodizing failed to provide the necessary wear resistance. Cerakote has proven to deliver lasting strength and durability, and we haven’t looked back since. It’s more durable than powder coating!

Even the oil and gas industry is increasingly switching from Xylan to Cerakote due to the latter’s high corrosion resistance.

Still not impressed? Along with offering outstanding performance, Cerakote looks great. The coating is available in dozens of colors, and the brand’s Mixology option allows us to create custom colors to match essentially any shade.

Get Stunning Quality from Our In-House Certified Cerakote Applicators

Anyone can apply Cerakote, but if you require expert Cerakote coating services, you need a Certified Cerakote Applicator to get the job done right. Fortunately, we have two of them right here in our precision machine shop, equipped with the training and expertise to give you a phenomenal finish with minimal lead time.

We recently sent these two employees for onsite Cerakote training in Medford, Oregon, where they were immersed in a rigorous 2-day training session. In just that short time, they were already producing higher-quality results than ever before.

By obtaining Cerakote certification and bringing Cerakote coating services in-house, our shop maintains total quality control over your coated parts—without the unavoidable delays of outsourcing the process to a partner shop.

The Cerakote coating process done right

Applying Cerakote requires a seemingly simple four-step process. We say “seemingly” because if any step is improperly performed or skipped, the coating can become compromised.

Step 1. Clean and degrease the part with acetone. We thoroughly clean the part of contaminants like grease, oils, and dust, making sure every crease and crevice is degreased. Cerakote won’t adhere properly to a part that hasn’t been degreased.

Step 2. Sandblast the part’s surface. Sandblasting adds texture to the part’s surface, allowing for optimal Cerakote adhesion. When shops cut corners on the Cerakote coating process, they tend to do it during this step. But we’ve found that sandblasting is truly critical to obtaining a quality coating.

Step 3. Spray the part with Cerakote. We evenly coat the part with wet Cerakote. If the substance dries too quickly, the finish won’t be smooth after curing.

Step 4. Allow the Cerakote finish to cure. The different types of Cerakote have varying curing requirements, from air curing to oven baking. Here at Area Tool & Manufacturing, Inc., we primarily coat parts with Cerakote’s H Series coatings, which must be oven cured; this process takes about two hours. H Series coatings offer optimal hardness, adhesion, flexibility, and wear resistance. However, if you need Cerakote coating services for a material that can’t withstand the heat of the curing oven, we can use a different coating that air-cures.

What Can We Cerakote for You?

The Area Tool & Manufacturing, Inc. team is excited to bring the Cerakote experience to all of our customers! Our Certified Cerakote Applicators can apply Cerakote to new or existing parts and products—the more unusual, the better!

Ask us about Cerakote coating services for knives and guns, PlayStation controllers, sunglasses frames, sports helmets—if it has a hard surface, we can probably Cerakote it.