Smart Design Solutions for Precision Machining Customers

At Area Tool & Manufacturing, Inc., we’re proud to say we’re setting new standards for precision machine shops everywhere.

We don’t just receive your print and make your parts. We go a step further, ensuring your parts are perfectly machined to function exactly as needed. That often means collaborating closely with your team to optimize your part designs for fast and cost-effective manufacturing.

Here are the true stories behind three real projects. Learn how we leveraged Design for Manufacturing (DFM) and Design for Assembly (DFA) best practices to give our customers top-quality parts and exceed their expectations.

Problem 1: The Misaligned Assembly

At first glance, this job for one of our medical customers appeared simple: precision machining the parts for a basic assembly. Upon further inspection, however, we realized there was no way to correctly align the bottom part to the top part. Instead, assemblers would have to manually align the components in a time-consuming, inexact process that was far from efficient.

We contacted the engineer right away, described our concern, and offered a solution—one he hadn’t considered. With a few simple design modifications, we could enable the parts to lock into perfect alignment during assembly.

To prove our solution, we adjusted the drawings and 3D model. Then we sent the files to the engineer for review. He not only approved our approach but also modified his files to reflect our DFA recommendations!

With the updated prints and models in our hands, we made the improved parts and delivered them to our customer, confident that the assembly process would now be quick and seamless.

Problem 2: The Stuck Springs

It’s not uncommon for our medical customers to purchase automation machines built with stock parts made by OEMS. But sometimes, these “off-the-rack” parts can impede a machine’s performance. These customers often come to Area Tool & Manufacturing, Inc. for help redesigning the OEM parts for optimized performance in their machines.

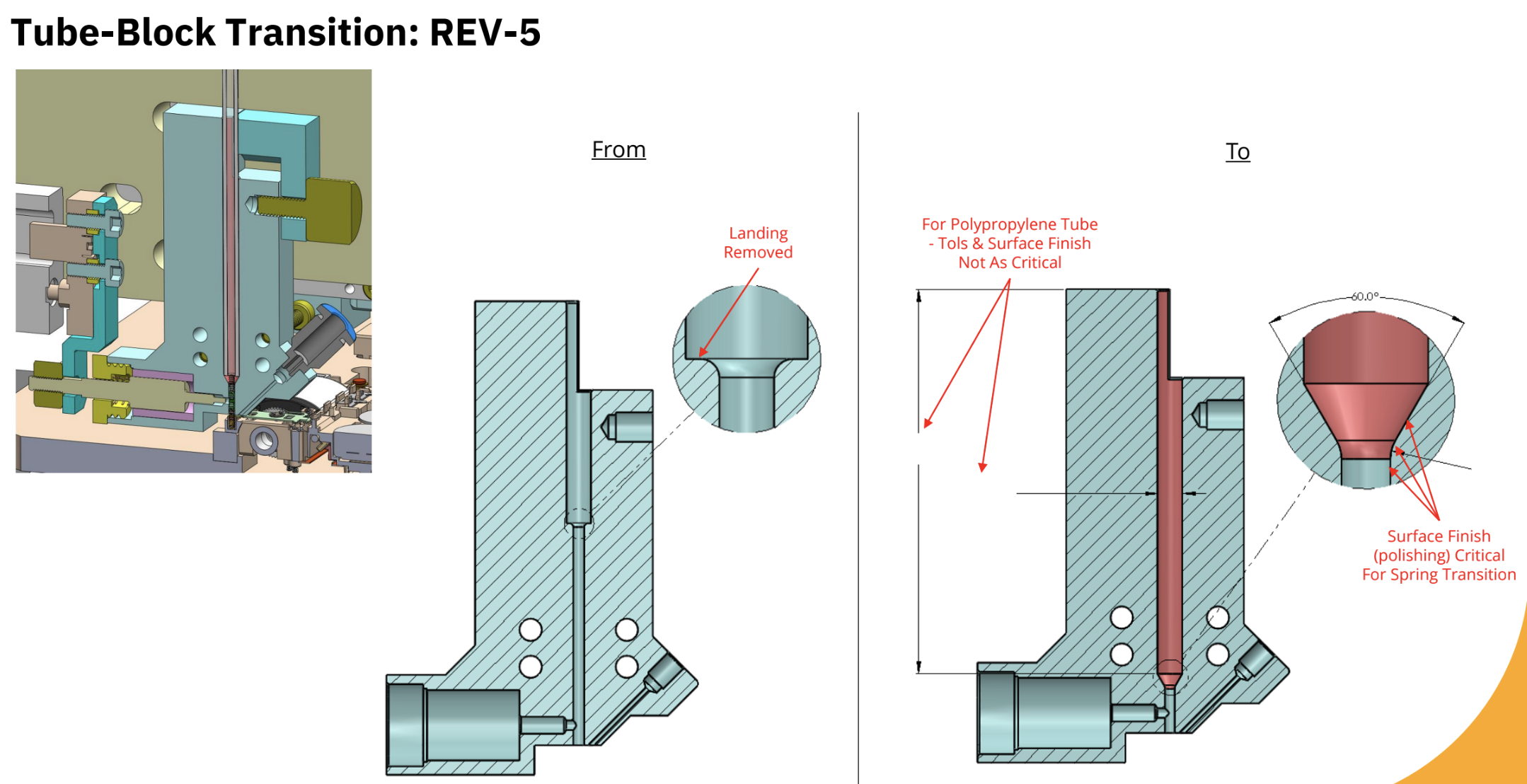

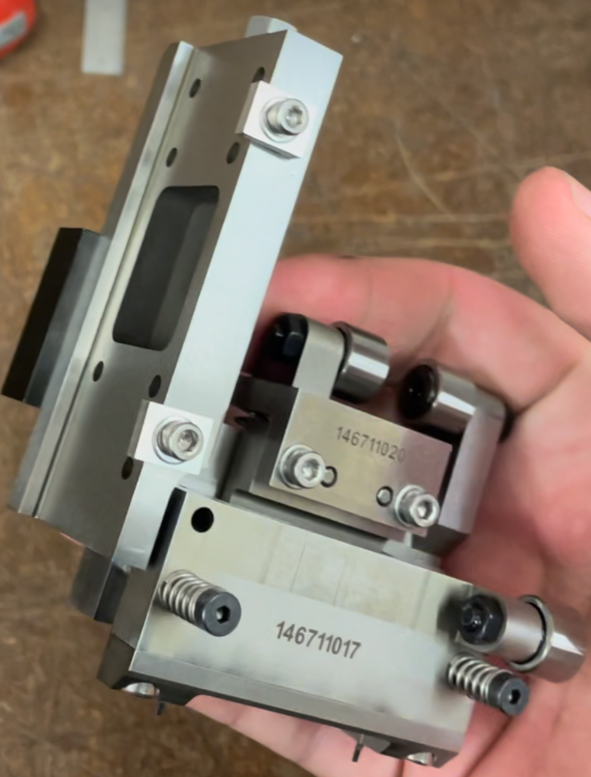

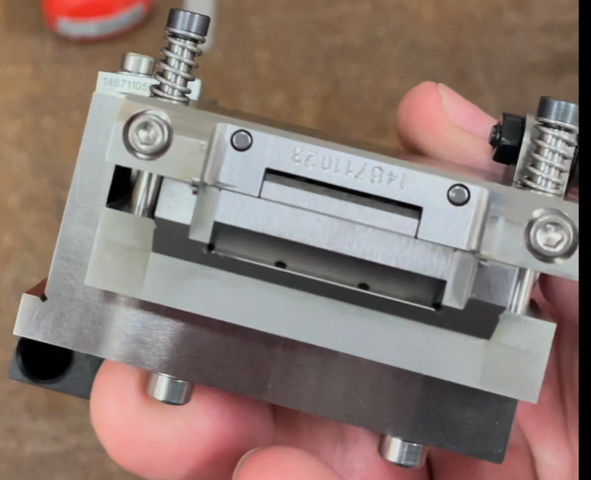

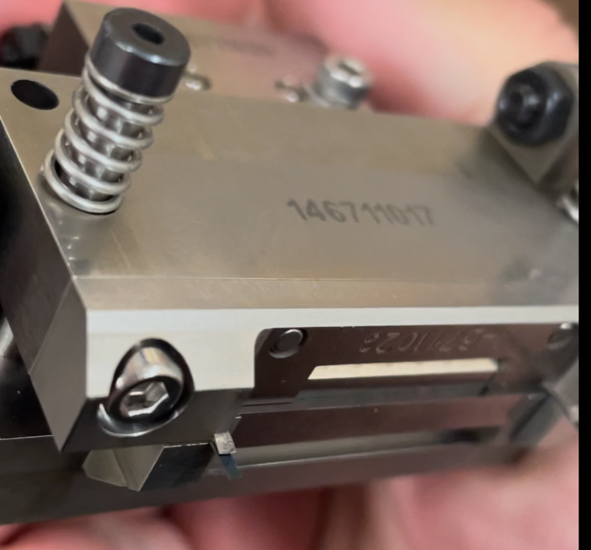

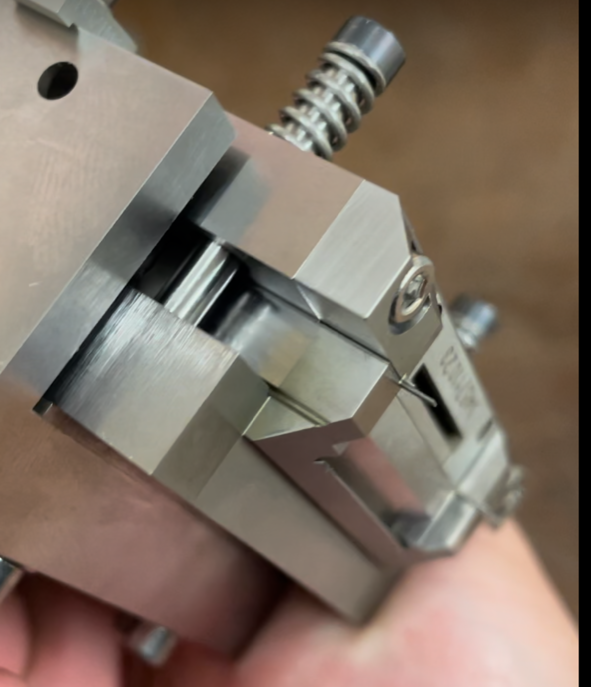

One engineer reached out to us after his team redesigned a part that had been causing problems in their automation machine. The part at fault was an aluminum block through which small springs were distributed from a plastic tube with the aid of an air plunger. Everything about the machine had worked well except for this block. The springs kept jamming.

Our customer’s redesigned part looked dramatically different from the original; it also called for A2 tool steel instead of aluminum. But when we delivered the new parts as designed, the results were dismal.

A second revision afforded minor improvements, but our customer wanted still more reliability and consistency from their machine. So we joined their team on a call where they presented six revision concepts and asked for our input.

After testing a series of incremental revisions, we agreed that the remaining issues could be due to magnetism in the A2 tool steel. Of course, our precision machine shop demagnetizes all applicable steels, but we knew a trace of magnetism could still be present—and might even be caused by the springs passing through the block.

To eliminate the possibility of magnetism, we suggested changing the material back to aluminum. This solution, plus some additional tweaks to the design, should further the goal of maximizing the machine’s output.

Soon, our customer will begin testing this round of parts, and we have high hopes that they’ll meet their production goals. But more importantly, we’re glad we can say that we never give up when a customer needs help. We’ll continue to work with them every step of the way to identify opportunities for improvement and make custom parts that outperform any stock parts.

Problem 3: The Price of Precision

From the very beginning, we knew our medical customer’s high-precision, 27-part assembly left no room for error. To ensure the best possible results, we held a call with the customer’s engineers and walked through every aspect of the project. We discussed which features would be particularly difficult to machine, which parts would be quite costly to make, and what risks were involved.

After an hour-and-a-half of reviewing and revising, our teams settled on a plan. We got to work manufacturing all 27 parts and then assembled them in our precision machine shop.

This customer would have never received such a high level of care and attention if they had sourced the components for this complex assembly from different shops. In fact, chances are they would have ended up with a non-functioning assembly because none of the shops would have been thinking about the assembly holistically.

Our ability to make parts and assemble them in-house is a critical advantage for customers seeking high-precision parts, and we’re honored to provide full assembly services.

Serious Precision Machining Solutions Start Here

Sometimes a problem demands a macro solution, like adding a capability to help our customers save money and enjoy better quality. Obtaining our Cerakote certification and bringing laser engraving in-house are two examples of macro problem-solving.

But most of the problems shops and their customers encounter on a day-to-day basis require problem-solving on a much smaller scale. Not every challenge can be resolved by expanding capabilities. Sometimes all that’s needed is a call with an engineer, a DFM or DFA recommendation, or a simple shift to an alternative material.

In the end, what matters most is giving our customers a great experience every day, for every order.

Get that experience for yourself! Request a quote.